Japanese candles, or Warosoku, are very different from regular Western candles. People often confuse the two because of their similar attributes. Some Japanese candles are easy to differentiate from other typical candles because of their distinctive shapes, like the Ikari-gata.

Haze Wax

A common plant source is haze wax, derived from haze trees. Their berries are crushed, steamed, and squeezed to extract the wax. An artisan can dip his bare hands into melted haze wax during the candle-making process because of its low melting point.

Rice Bran Wax

Rice bran wax is obtained through winterisation or cold press of rice bran oil. This process yields a hard and yellow wax with a high melting point. Japanese candles made from this feel silky and non-tacky to the touch.

Palm Wax

Warosoku is sometimes made from palm wax, which is extracted from palm fruits. These candles produce less soot as compared to Western candles made from paraffin wax. In addition, palm-based candles have a longer burning time.

Soy Wax

Another plant source is soybeans. Japanese candles with soy wax burn slowly at a low temperature and are ideally used as aroma candles. It also doubles as a relaxing massage oil! Soy wax is natural moisturisers, and people have created their own candles to test it on their skin. They are usually burnt for 10 to 20 minutes and cooled before the skin can be dipped inside. Due to its low melting point, it just feels like warm silk on the skin. Furthermore, aromatherapy massages have combined this nourishing elixir with essential oils to invigorate the senses.

How Are Japanese Candles Made?

Making the wick

The Japanese candlewick is thicker and more rigid than the Western one. The candle maker uses a long piece of Japanese paper, or washi, and wraps it around a stick.

Making the Japanese candles

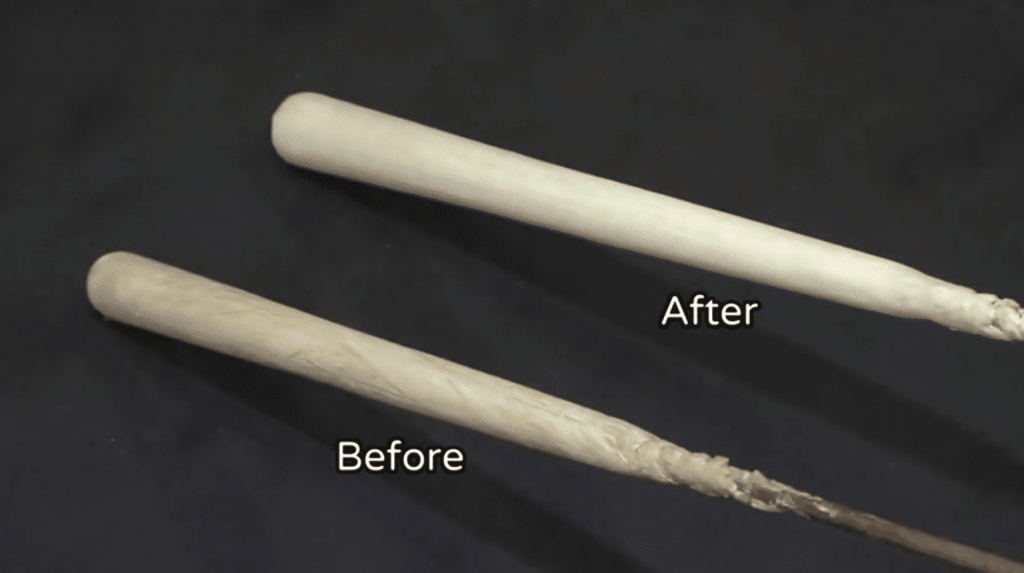

Next, in a process called Shitagake, the wicks are coated with wax by hand. By now, the temperature of the wax is 46 degrees Celsius, which allows the candle maker to handle it by hand.

Finishing process

The candle maker scrapes the ends to expose the wicks. The wooden sticks that hold the wax together are also removed. Lastly, the candles are cut to their desired lengths.